Screw Compressor

Elite Air’s EA Series screw air compressors are designed to meet diverse industrial demands, offering a comprehensive range of power options for applications ranging from light-duty to heavy-duty. This series combines robust structural design with advanced intelligent control technology, ensuring superior reliability and operational efficiency even in demanding manufacturing environments.

To meet the stringent requirements of modern industry for energy conservation and cost reduction, the entire EA series now offers an optional “Variable Speed Drive (VSD)” function. Through advanced VSD technology, the compressor precisely adjusts motor speed according to actual air demand, eliminating the energy consumption typically associated with unloaded operation in fixed-speed machines. This not only achieves significant energy savings but also provides more stable system pressure and reduces impact on the power grid through soft starts, ultimately extending equipment lifespan.

Every EA series compressor (whether standard fixed speed or VSD equipped) is paired with high-efficiency motors and sophisticated microcomputer controllers. These provide real-time operation monitoring and multiple safety protections, making the EA Series the most trusted foundation for enhancing your facility’s productivity.

Manufacturing Specification Range Overview

Based on our complete EA Series product line (covering models from EA 05A to EA 315A), our manufacturing specification range is as follows:

Drive Options: Standard Fixed Speed or Optional High-Efficiency VSD (Variable Speed Drive)

Motor Power Range: 5.5 kW (7.5 HP) to 315 kW (420 HP)

Working Pressure: Standard configurations of 8 / 10 / 13 Bar (Optional up to 16 Bar on select models)

Capacity (FAD): 0.40 m³/min to 55.2 m³/min (VSD models offer a wider turndown range)

Voltage / Frequency: Supports 220 / 380 / 415 / 440V (50/60Hz 3-Phase)

Capacity Control: On/Off control, Stepless capacity control, or precise VSD PID control depending on configuration.

Motor Specification: High-Efficiency TEFC (Totally Enclosed Fan Cooled), F-Class Insulation, IP54 Protection Grade.

Cooling Medium: Air Cooled

Intelligent Controller: Equipped with a microcomputer digital controller featuring temperature/pressure display, automatic run/stop logic, multiple safety protections, and maintenance indications.

2 Stage Screw Compressor

EAV Series 2-Stage VSD Screw Compressor

The Elite Air EAV Series represents the pinnacle of energy-efficient compressed air technology, now expanded to support heavy-duty industrial applications up to 355 kW (480 HP). This series combines advanced two-stage compression with standard Variable Speed Drive (VSD) capability across the entire range.

By utilizing a dual-stage compression process, the compression ratio across each stage is lowered. This significantly reduces bearing loads and thermal stress while maximizing volumetric efficiency compared to single-stage alternatives. This inherent mechanical efficiency is further amplified by integrated VSD technology (Inverter Starting), which precisely matches motor speed to actual air demand, eliminating wasteful unloaded running and providing stable, constant pressure output.

For our larger capacity models, we incorporate ultra-efficient IE4 Super Premium Efficiency motors, further maximizing energy savings and reducing the total cost of ownership for large-scale operations. Designed with robust direct drive and capable of operating in demanding environments, the EAV Series is the ultimate investment for long-term industrial sustainability.

Manufacturing Specification Range Overview

Based on our expanded EAV Series product line (covering models from EAV 30AD up to the heavy-duty EAV 355AD), our manufacturing specification range is as follows:

- Compression Type: High-Efficiency Two-Stage (Double Screw)

- Drive & Starting Method: Direct Drive with Inverter (VSD) Starting standard on all models.

- Motor Power Range: Expanded range from 30 kW up to massive 355 kW (480 HP) models.

- Motor Efficiency: Utilizing high-efficiency motors, with IE4 Super Premium Efficiency available on large capacity models.

- Working Pressure Capability: Capable of covering a wide pressure spectrum (typically 4.5 Bar up to 12.5 Bar depending on configuration).

- Control Method: Automatic control with status display; Frequency Control range typically 40~100% for precise output adjustment.

- Cooling Options: Available in Air-Cooling or Water-Cooling configurations to suit plant infrastructure.

- Operating Environment: Designed for high ambient temperatures (up to 52°C for standard models).

- Safety Protection: Comprehensive device protection including high temperature, high pressure, blockage, overcurrent, phase loss, reverse phase, and voltage instability.

- Protection Level: IP54 sealed protection for electric motors.

OIL FREE SCREW

EAO Series Oil-Free Screw Compressor

The Elite Air EAO Series is designed for industries where air purity is non-negotiable. Delivering 100% oil-free guaranteed compressed air, this series meets the most stringent air quality standards required by sectors such as food and beverage processing, pharmaceutical manufacturing, electronics, and high-quality painting.

Beyond exceptional air purity, the EAO Series is engineered for efficiency and reliability. Every model in this range comes standard with Inverter (VSD) Starting technology, which significantly reduces starting current surges and allows for precise matching of energy consumption to air demand. Combined with a robust direct-drive transmission system, the EAO Series ensures minimal energy loss, reduced maintenance requirements, and a long operational lifespan, providing a sustainable and cost-effective solution for critical applications.

Manufacturing Specification Range Overview

Based on our EAO Series product line, our manufacturing specification range is as follows:

- Compression Type: Oil-Free Screw Compressor (ensuring 100% contaminant-free air).

- Starting & Control Method: Inverter (VSD) Starting standard on all models for maximum energy efficiency and smooth operation.

- Drive Method: Direct Drive for high transmission efficiency.

- Motor Power Range: 37 kW to 90 kW (and extending up to 160kW as shown in the broader spec sheet).

- Working Pressure Options: Available in 7, 8, or 10 Bar configurations to suit various application needs.

- Flow Rate / Capacity (FAD): Ranges from approximately 5.80 m³/min to over 29.52 m³/min (depending on model and pressure selection).

- Cooling Method: Air Cooled design.

- Motor Protection: IP54 Protection Level, ensuring reliable operation in industrial environments.

PORTABLE COMPRESSOR

Elite Air Diesel Driven Portable Compressor Series

The Elite Air Diesel Driven Portable Compressor Series is engineered for mobility, durability, and reliable performance in the most demanding off-grid environments. Designed for construction sites, mining operations, roadworks, and remote industrial projects, these compressors deliver powerful compressed air wherever you need it, independent of electrical power sources.

Our portable range features robust, weather-resistant enclosures built to withstand harsh field conditions. Powered by world-renowned diesel engines—including Cummins, Yuchai, Kubota, Caterpillar, and Volvo—these units ensure exceptional fuel efficiency, low emissions, and long operational life. The series offers a broad spectrum of pressure and flow configurations, from standard models for pneumatic tools to high-pressure units suitable for drilling and specialized applications.

With integrated towing systems and user-friendly control panels, the Elite Air Portable Series provides the ultimate combination of on-site flexibility, powerful output, and rugged reliability to keep your outdoor operations running smoothly.

Manufacturing Specification Range Overview

Based on our Diesel Driven Portable Compressor product line (covering multiple series with various engine brands), our manufacturing specification range is as follows:

- Compression Type: Portable Screw Compressor powered by a Diesel Engine.

- Engine Brands: Features reliable engines from Cummins, Yuchai, Kubota, Caterpillar, and Volvo (depending on model).

- Rated Engine Power: Ranges from 49 HP to a massive 760 HP.

- Working Pressure Options: Extremely wide range to suit diverse applications:

- Standard Pressure: 7 Bar (100 psi) to 14 Bar (200 psi)

- Medium-High Pressure: 15 Bar (220 psi) to 25 Bar (360 psi)

- High Pressure: Up to 35 Bar (500 psi)

- Capacity (FAD): Broad flow range from 5 m³/min (175 cfm) up to 65 m³/min (2300 cfm) for large-scale operations.

- Mobility: Designed with a rugged chassis and tow bar for easy transportation (Dimensions and weight vary significantly by model, from compact 900kg units to large 8478kg trailers).

- Outlet Connections: Multiple outlet sizes available (e.g., G1, G2, G3/4, NPT) to accommodate various site requirements.

ALL IN ONE SCREW

ZS Series All-In-One Laser Cutting Compressor

The Elite Air ZS Series is a specialized, integrated compressed air solution specifically engineered for the demanding requirements of laser cutting applications. This “All-In-One” station combines a high-performance screw compressor, a refrigerated air dryer, a large-capacity air receiver tank, and multi-stage precision filters into a single, compact unit.

Designed to deliver stable, high-pressure air (1.6 Mpa / 16 Bar) that is exceptionally dry and clean, the ZS Series ensures optimal laser cutting quality, prevents lens contamination, and extends the lifespan of your valuable laser cutting equipment.Its plug-and-play design simplifies installation, reduces footprint, and minimizes pressure drop across components, providing a reliable and energy-efficient power source for your laser cutting operations.

Manufacturing Specification Range Overview

Based on our ZS Series “All-In-One” product line (covering models from ZS8A to ZS22A), our manufacturing specification range is as follows:

- Configuration: Integrated “All-In-One” station (Compressor + Dryer + Tank + Filters).

- Application Focus: Specifically optimized for Laser Cutting machines.

- Compression Stage: Single Stage.

- Motor Power Range: 7.5 kW (10 HP) to 22 kW (30 HP).

- Working Pressure: Standardized high pressure of 1.6 Mpa (16 Bar) across all models.

- Free Air Delivery (FAD): Ranges from 0.48 m³/min to 1.75 m³/min at 1.6 Mpa.

- Drive Method: Belt Driven.

- Starting Method: Direct Starting (for ZS8A) or Y-Δ Starter (Star-Delta starting for ZS11A and larger).

- Cooling Mode: Air-Cooling.

- Electricity: 380V / 3-Phase / 50Hz.

- Noise Level: Relatively quiet operation (62±2 to 64±2 dB).

- Air Outlet Diameter: 3/4″ or 1″.

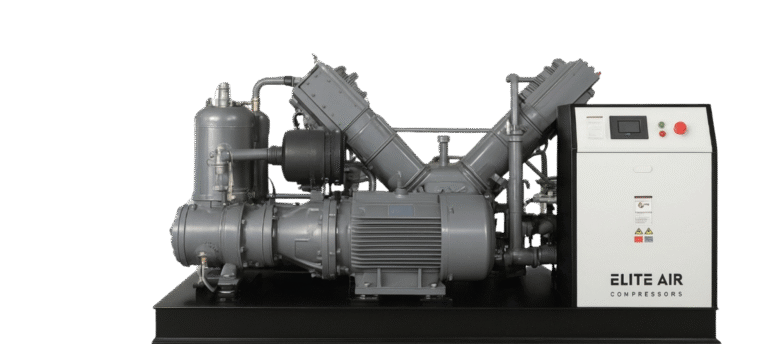

Screw Plus Booster Compressor

EVB Series Screw Plus Booster Compressor

The Elite Air EVB Series is a high-performance oil-free booster compressor designed to take your existing compressed air system to the next level. It effectively elevates standard plant air pressure to high-pressure levels (30-40 kg/cm² / bar) while ensuring the output remains 100% oil-free.

Engineered for demanding industrial applications such as PET bottle blowing, leak testing, and specialized gas transport, the EVB Series delivers reliable, high-pressure, contaminant-free air. Its robust design ensures continuous, heavy-duty operation, making it the ideal solution for processes where both high pressure and absolute air purity are critical requirements.

Manufacturing Specification Range Overview

Based on our EVB Series product line (covering models from EVB-60 to EVB-400), our manufacturing specification range is as follows:

- Compression Type: Oil-Free Booster Compressor (requires pre-compressed inlet air).

- Application Focus: High-pressure oil-free applications like PET blowing.

- Motor Power Range: Significant power options from 67 kW to 410 kW.

- Free Air Delivery (FAD): Ranges from 6 m³/min up to 40 m³/min (at high pressure).

- Working Pressure: Designed for high-pressure output of 30-40 kg/cm² (approx. 30-40 Bar) across all models.

- Cooling Method: Water Cooled (requires a cooling water source).

- Water Consumption: Significant cooling water flow required, ranging from 20 T/h up to 90 T/h.

- Weight: Heavy-duty construction, ranging from 3000 kg up to 13000 kg.

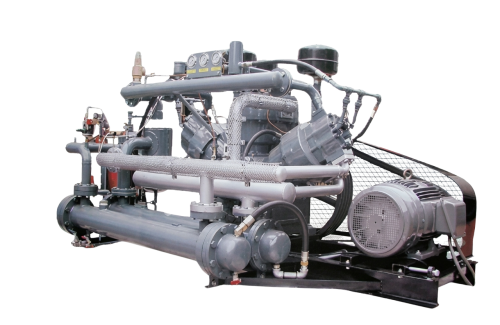

Oil Free High Pressure Compressor

HNLD Series Oil-Free High-Pressure Compressor

The Elite Air HNLD Series is a specialized, heavy-duty compressor solution designed for applications requiring both 40 Bar high pressure and 100% oil-free air quality. It is particularly suited for critical industrial processes such as PET bottle blowing, where any trace of oil contamination is unacceptable, and high pressure is essential for shaping.

This series utilizes a robust, multi-stage compression design (L, M, H stages) to efficiently achieve high pressure while maintaining low operating temperatures. Engineered for continuous, reliable operation in demanding environments, the HNLD Series features a low-RPM design for reduced wear and extended component life. The water-cooled system ensures optimal thermal management, guaranteeing consistent performance and high-quality air output for your most critical applications.

Manufacturing Specification Range Overview

Based on our HNLD Series product line (covering models from HNLD-50S to HNLD-350S), our manufacturing specification range is as follows:

- Compression Type: Oil-Free High-Pressure Multi-Stage Compressor.

- Application Focus: Ideal for PET blowing and other high-pressure, oil-free applications.

- Working Pressure: Standardized high pressure of 40 Bar across all models.

- Motor Power Range: Significant power options from 37 kW (50 HP) to 260 kW (350 HP).

- Capacity (FAD): Ranges from 3.5 m³/min up to 24.8 m³/min at 40 Bar.

- Operating Speed (Rev): Low-speed design ranging from 230 RPM to 460 RPM for durability.

- Cooling Method: Water Cooled (requires significant cooling water flow, from 160 L/min to 840 L/min).

- Compression Structure: Multi-stage design (Low, Medium, High pressure stages) with varying bore and stroke dimensions for efficient high-pressure generation.

High Pressure Air Cool

EAH Series High-Pressure Compressor

The Elite Air EAH Series is engineered specifically for industrial applications demanding reliable, high-pressure compressed air up to 30-40 Bar. Designed to withstand the rigors of heavy-duty operation, this series is the ideal power source for specialized processes such as leak testing, valve actuation, pneumatic clamping, and certain stages of PET manufacturing.

The EAH Series offers exceptional versatility through its wide range of models. From compact units for specific high-pressure tasks to larger, scalable configurations (such as the EAH-20×4), this series can deliver the necessary high pressure combined with higher flow rates to meet growing operational demands. Its robust construction ensures long-term durability and consistent performance in critical high-pressure environments.

Manufacturing Specification Range Overview

Based on our EAH Series High-Pressure product line (covering models from EAH15A to EAH-20×4), our manufacturing specification range is as follows:

- Compression Type: High-Pressure Industrial Compressor.

- Application Focus: Designed for applications requiring pressure significantly higher than standard industrial air.

- Working Pressure: Standardized high-pressure range of 30-40 Bar across all models.

- Motor Power Range: 11 kW (15 HP) to 60 kW (80 HP).

- Capacity (Flow Rate): Ranges from approx. 0.6 m³/min up to 4.8 m³/min (depending on pressure setting and model configuration).

- Configuration: Available in single units and larger, multi-unit configurations for increased capacity.

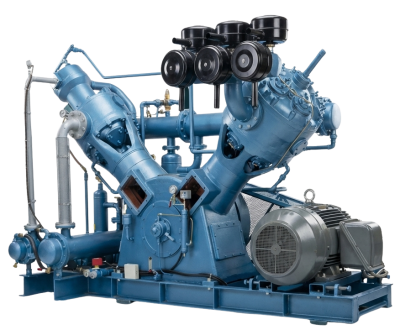

High Pressure Water Cool

HA/HRW Series Heavy-Duty High-Pressure Compressor

The Elite Air HA/HRW Series is a robust line of high-pressure compressors engineered for industrial applications requiring reliable compressed air in the 15-35 Bar range. Built for endurance, this series is the preferred choice for demanding applications such as PET bottle blowing (pre-blowing stages), leak detection, engine starting, and powering heavy-duty pneumatic machinery.

A key feature of the HA/HRW Series is its low-RPM design (running between 450 and 770 RPM). This deliberate design choice significantly reduces wear on internal components, lowers operating temperatures, and minimizes vibration, resulting in exceptional durability, extended service intervals, and a long operational lifespan even under continuous, heavy loads. Its heavy-duty construction ensures stable performance in the toughest industrial environments.

Manufacturing Specification Range Overview

Based on our HA/HRW Series High-Pressure product line (covering models from HA-20 to HRW-125), our manufacturing specification range is as follows:

- Compression Type: Heavy-Duty High-Pressure Industrial Compressor.

- Application Focus: Ideal for medium-high pressure applications demanding high durability and continuous operation.

- Working Pressure: Adjustable high-pressure range of 15-35 Bar across all models.

- Motor Power Range: 15 kW (20 HP) to 90 kW (125 HP).

- Capacity (Flow Rate): Ranges from 1.1 m³/min up to 7.6 m³/min.

- Operating Speed (R.P.M): Low-speed design (450 – 770 RPM) for enhanced durability and reduced wear.

- Construction: Heavy-duty build quality for long-term reliability.

Air Dryer

EAD Series Refrigerated Air Dryer

Untreated compressed air always contains moisture, which can cause corrosion in pipework, damage pneumatic tools, and compromise final product quality. The Elite Air EAD Series Refrigerated Air Dryers provide the essential solution by effectively removing water vapor from your compressed air system.

By utilizing a robust refrigeration circuit, the EAD Series cools the compressed air, causing moisture to condense and be separated from the air stream. The result is a dry, clean air supply that protects your equipment and processes. Designed for industrial reliability, these dryers can handle high inlet temperatures (up to 80°C) and use environmentally friendly refrigerants (R410A/R407c), offering a dependable and eco-conscious solution for maintaining system integrity.

Manufacturing Specification Range Overview

Based on our EAD Series Air Dryer product line (covering models from EAD 10A to EAD 1300A), our manufacturing specification range is as follows:

- Product Type: Refrigerated Air Dryer (for removing moisture from compressed air).

- Capacity (Air Flow): Extremely wide range from 1.4 m³/min to 130 m³/min, suitable for small to very large-scale operations.

- Working Pressure: Standardized at 10 Bar.

- Inlet Temperature: Rated for 55°C, capable of handling maximum inlet temperatures up to 80°C.

- Refrigerant: Uses modern, environmentally friendlier refrigerants (R410A for smaller models, R407c for larger models).

- Power Supply: Available in single-phase (220V) for smaller units and three-phase (380V) for larger units.

- Connection Size: Ranges from 1″ up to 6″ pipe connections.

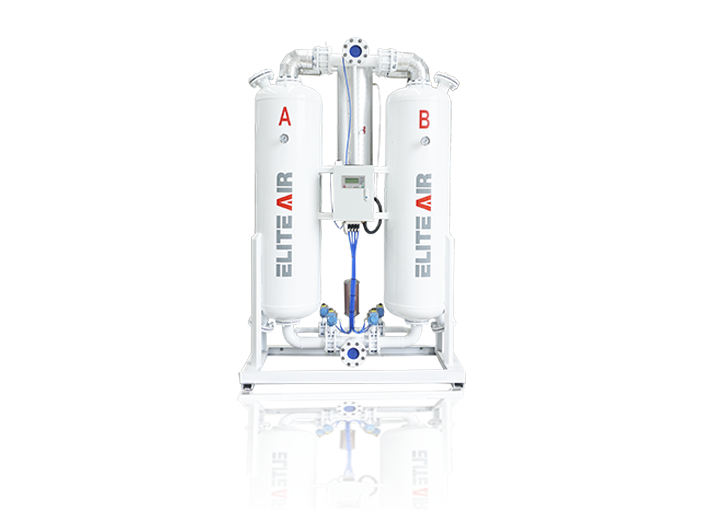

Desiccant Dryer

Elite Air Desiccant Dryer Series

When your industrial application demands ultra-dry compressed air beyond the capabilities of a standard refrigerated dryer, the Elite Air Desiccant Dryer Series is the definitive solution. Engineered to deliver exceptionally low pressure dew points down to -40°C or -70°C, this series ensures virtually moisture-free air, even in freezing ambient conditions.

The system utilizes twin towers filled with high-performance desiccant material (such as activated alumina or molecular sieve). While one tower is actively adsorbing moisture from the air stream under pressure, the other tower is regenerating (drying) its desiccant. This continuous, automatic cycle provides a constant supply of super-dry air, which is critical for preventing freezing in outdoor airlines, protecting sensitive pneumatic instruments, and ensuring the quality of processes like powder coating, electronics manufacturing, and pharmaceutical packaging.

Manufacturing Specification Range Overview

Based on our F Series Desiccant Dryer product line (covering models from F-1 to F-200), our manufacturing specification range is as follows:

- Product Type: Heatless Regenerative Desiccant Air Dryer (for achieving ultra-low dew points).

- Application Focus: Critical applications requiring extremely dry air (e.g., electronics, outdoor piping, sensitive instruments).

- Capacity (Air Flow): Wide range from 1.2 Nm³/min (42 cfm) up to a massive 200 Nm³/min (7070 cfm).

- Pressure Dew Point: Capable of achieving ultra-low dew points of -40°C to -70°C, ensuring superior dryness.

- Connection Size: Ranges from 1″ up to large 10″ flanges.

- Power Supply: Standard 220V / 1 Phase / 50Hz for the control system.

- Operation: Twin-tower design with automatic regeneration cycle.

Air-Cooled Screw Water Chiller

Air-Cooled Screw Water Chiller

It adopts the internationally famous brand of Taiwan Hanbell and BITZER screw compressors, and condenser is made of high quality and high efficiency copper tube. The evaporator and world famous brand spareparts make the unit have the adventages of small volume, low noise, high energy, log service life ans simple operation. With its beautiful design and consistent high performance, it is the best its class

Box Plate

- The compressor adopts the international brand new high-efficiency screw type rotary compressor, which is 20-30% more energy efficient than the general compressor

- It has obtained patents from many countries in Europe and America, and has passed the IOS9001:2000 international quality certification

- Efficient 5:6 patent asymmetrical gear shape

- Capacity control can be four-stage (100%-75%-50%-25%) or three-stage (100%-66%-33%) and non-stage control system

- The combination design of 11 bearings and a type axial thrust balancing drum greatly increases the bearing life by 2.5-3.5 times

- All round compressor capacity ratio (V1-2.2/2.6/3.0/3.5) can be selected, which can effectively avoid additional energy consumption to compressor overload or insufficient compressor pressur

Water Cooled Chiller

Water Cooled Chiller

It is manufactured by modern advanced technology with excellent quality and beautiful appearance. Colling capacity from 12,52oKcal/hr to 250.000Kcal/hr (50HP-100HP). It can be widely used in chemical, food, plastic, electroplating, concrete mixing plant, laser, printing, circuit board and other industrial chilled water field

Evaporators

The inner surface of the copper tube is threaded, the copper tube has a smooth appearance and good cooling effect. The evaporator tubr is insulated with 26mm thick PE insulation board. No dew, less cold loss

Condenser

The condenser is equipped with high-efficiency cross-seam find and internally threaded copper tubes for high heat exchange efficiency and stabillity

Box Plate

The box plate of the fully enclosed chiller set is precision machined by CNC punching machine and painted with electrostatic powder, which is luxurious and beautiful in appreance and has good sound insulation effect

Air Cooled Chiller

Air Cooled Chiller

It is manufactured by modern advanced technology with excellent quality and beautiful appearance. Colling capacity from 12,52oKcal/hr to 250.000Kcal/hr (50HP-100HP). It can be widely used in chemical, food, plastic, electroplating, concrete mixing plant, laser, printing, circuit board and other industrial chilled water field

Evaporators

The inner surface of the copper tube is threaded, the copper tube has a smooth appearance and good cooling effect. The evaporator tuber is insulated with 26mm thick PE insulation board. No dew, less cold loss

Condenser

The condenser is equipped with high-efficiency cross-seam find and internally threaded copper tubes for high heat exchange efficiency and stability

Box Plate

The box plate of the fully enclosed chiller set is precision machined by CNC punching machine and painted with electrostatic powder, which is luxurious and beautiful in appearance and has good sound insulation effect

Scroll Water Chiller

Scroll Water Chiller

Compressor

The water-cooled screw chiller are all made of famous brand semi-hermatic screw compressor. Its 5:6 super efficient screw rotor design, 20-30%

more efficient than the average compressor. It has the advantages of smooth and realiable operation, high efficiency, low failure rate and easy maintance. The compressor can automatically alternate operation according to load change, balancing the running hour of each compressor, greatly extending the service life of the chiller unit, trouble-free operation up to 45000 hour, or more

Energy-Efficient Condensers and Evaporator

The condenser adopts German and Japanese original copper tubes, which are processed into trapezodial low-rib tubes to enhance heat transfer capacity. The inner surface of the copper tube becomes smooth so that the water pressure is reduced and easy to clean and maintain. The evaporator adopts a reinforced copper tube with inner and outer threads, the copper tube has good cooling effect. The evaporator barrelis insulated with a 25mm thick PE insulation board. No condesation and less cooling loss

Double Screw Water Chiller

Double Head Screw Water

Compressor

The water-cooled screw chillers are all made of famous brand semi-hermatic screw compressor. Its 5:6 super efficient screw rotor design, 20-30%

more efficient than the average compressor. It has the advantages of smooth and reliable operation, high efficiency, low failure rate and easy maintainer. The compressor can automatically alternate operation according to load change, balancing the running hour of each compressor, greatly extending the service life of the chiller unit, trouble-free operation up to 45000 hour, or more

Energy-Efficient Condensers and Evaporator

The condenser adopts German and Japanese original copper tubes, which are processed into trapezoidal low-rib tubes to enhance heat transfer capacity. The inner surface of the copper tube becomes smooth so that the water pressure is reduced and easy to clean and maintain. The evaporator adopts a reinforced copper tube with inner and outer threads, the copper tube has good cooling effect. The evaporator barrel is insulated with a 25mm thick PE insulation board. No condensation and less cooling loss